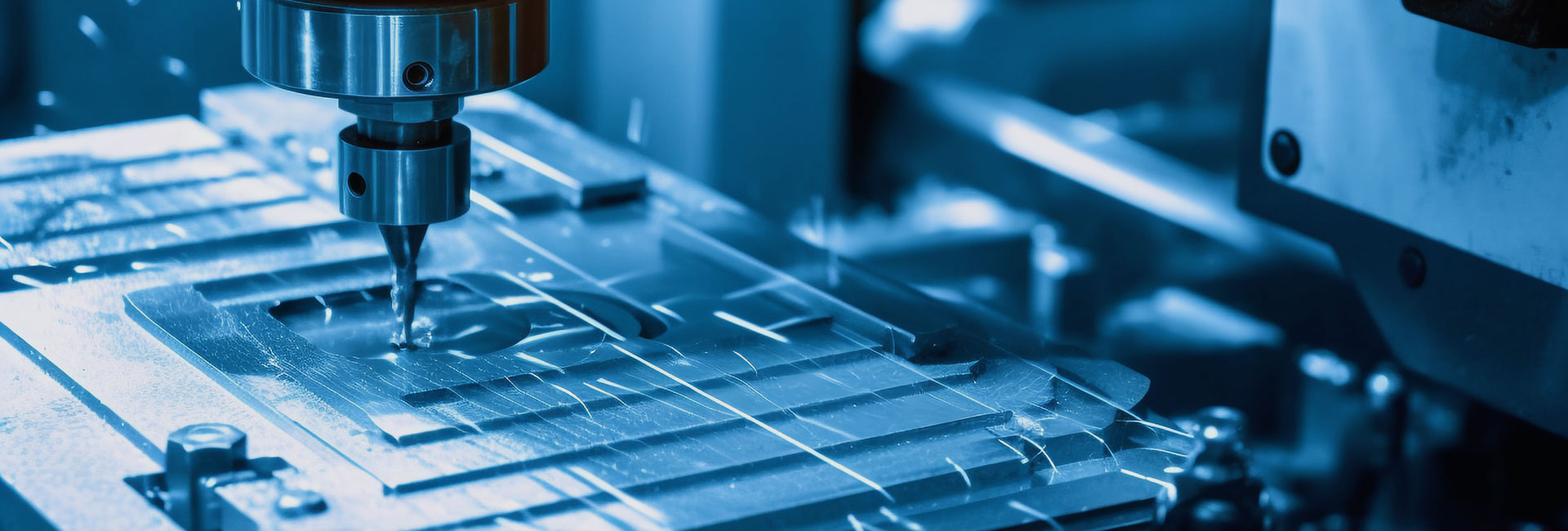

At the end of 2012, the procurement team from Electrolux's Water Tank Technology Center came to China to find a new supplier for the production of pop-up steam tanks. After the recommendation of Jinfa Technology (China's largest listed modified plastics company), Jieyuan Electrical Appliances entered Electrolux's supplier list as a potential high-quality supplier representative. The perfect quality and production management system of Jieyuan Electrical appliances, the valuable experience of mass production quality control, production cost control and process control accumulated in the supply practice of global first-line brands for many years, and the rigorous style of engineers and R & D team that focuses on actual data collection, customer feedback and advance quality planning have been highly recognized by Electrolux. Since then, led by project leader Wu Shengdong (Tony), our Jieyuan project team began to communicate directly with the Italian water tank research and development team, and directly participated in the development and design of the customer's new project.

Tony admitted: In fact, the most difficult thing to solve is to improve the life of the pop-up movement, which is caused by the uneven wear force in the pop-up movement. The customer initially designed the version, after the test movement life is only about 1000 times, can not meet the actual use of consumer demand. The project team actively cooperated with customers to solve problems, defined testing standards and methods together with customers. The quality department made test equipment by itself, and the technical department developed and designed non-standard equipment by itself. Based on the data obtained from many experiments, the project team gave three suggestions to customers: make two points on the rack; Grease key locations; Adjust the position of the cushion. And cooperate with customers to do simple simulation display solutions, one by one verification. The project team crossed the river by feeling the stones, collected test data, extracted key information, optimized process parameters in the failure again and again, solved many problems, and finally reached the life requirements of 5000-10000 times of opening and closing required by the customer.

The whole life optimization process is not only the higher requirements of Electrolux's high-end customers for product quality, but also reflects our professional, systematic and fundamental ability to help customers solve problems.

During the development of the new project, other defects in the design process were discovered, such as the induction failure of the water level monitor pasted on the side of the tank, the dynamic sealing of the water and so on. The water tank project team maintained close contact and communication with customers through phone calls, emails, video conferences and other multiple ways, and passed test data and key information to customers in a timely manner. From design review and evaluation program, to making hand plates, verification program, and soft mold, we found various problems in processing and assembly and assisted in solving them, and highly cooperated with customer needs. Finally, in March 2014, we realized the mass production of Electrolux pop-up steam water tank components.

After mass production, the project team is still continuing to optimize and improve, and by 2023, the ejected steam tank assembly has been upgraded to the fifth generation of products.

Home

Home

Product

Product

News

News

Contact

Contact